As semiconductor applications become more specialized, generic silicon solutions are no longer enough. From AI accelerators and automotive electronics to IoT and high-speed networking, modern systems demand purpose-built silicon. This is where custom silicon services play a critical role—bridging innovative ideas with production-ready silicon.

Custom silicon services enable companies to design chips that are optimized for performance, power, area, and cost, while aligning precisely with application-specific requirements. This article explores the complete journey—from concept definition to silicon realization—and why custom silicon is becoming the foundation of next-generation products.

What Are Custom Silicon Services?

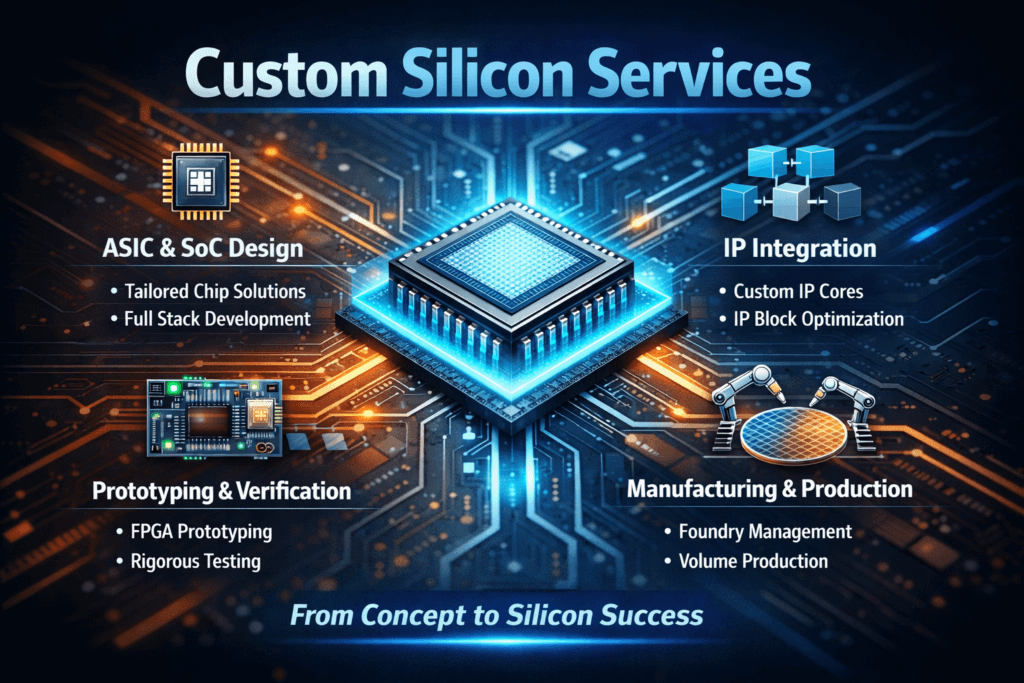

Custom silicon services refer to end-to-end semiconductor design and engineering solutions tailored to specific product requirements. Unlike off-the-shelf ICs, custom silicon is designed from the ground up to meet unique functional, performance, and integration goals.

These services typically cover:

- Architecture definition and feasibility analysis

- RTL design and functional verification

- Physical design and DFT

- Pre- and post-silicon validation

- Foundry interfacing and tape-out support

By leveraging custom silicon services, organizations gain full control over chip behavior, differentiation, and scalability.

From Concept to Architecture: Turning Ideas into Silicon-Ready Designs

The journey begins with a conceptual definition, where system requirements are translated into silicon specifications. This phase is critical, as early architectural decisions directly impact performance, power consumption, and manufacturability.

Key activities include:

- Workload analysis and system modeling

- Selection of process nodes and IP blocks

- Power, performance, and area (PPA) trade-off studies

- Risk assessment and design feasibility

A well-defined architecture ensures that the silicon design is aligned with both technical and business objectives from day one.

RTL Design and Functional Verification

Once the architecture is finalized, the design moves into RTL implementation. This stage involves developing synthesizable RTL code that accurately reflects the intended functionality of the chip.

Equally important is functional verification, which ensures correctness before silicon fabrication. Modern custom silicon services rely on:

- UVM-based verification environments

- Simulation, formal verification, and emulation

- Coverage-driven verification methodologies

Early detection of design issues at this stage significantly reduces costly re-spins and accelerates time-to-market.

Physical Design, DFT, and Sign-Off

After RTL validation, the design progresses to physical implementation, where logical designs are transformed into manufacturable layouts.

This phase includes:

- Floorplanning, placement, and routing

- Clock tree synthesis and timing closure

- Power integrity and signal integrity analysis

- Design for Testability (DFT) insertion and validation

Successful sign-off ensures the design meets foundry requirements and is ready for tape-out with confidence.

Silicon Validation and Post-Silicon Support

Custom silicon services do not stop at tape-out. Post-silicon validation ensures that fabricated silicon performs as intended in real-world conditions.

This stage covers:

- Bring-up and debug

- Performance benchmarking

- Power and thermal validation

- Failure analysis and yield optimization

Post-silicon support is essential for ensuring product reliability and readiness for volume production.

Why Custom Silicon Services Matter Today

The demand for custom silicon services is accelerating due to:

- Increased complexity of SoCs

- Need for domain-specific acceleration

- Tight power and performance constraints

- Competitive pressure for differentiation

Organizations that invest in custom silicon gain long-term advantages in innovation, efficiency, and system-level optimization.

Conclusion: Partnering with Silicon Patterns for Custom Silicon Excellence

From early architecture definition to post-silicon validation, custom silicon services require deep domain expertise, proven processes, and strong execution capabilities. This is where Silicon Patterns stands out.

With comprehensive experience across ASIC and SoC design, verification, physical implementation, DFT, and silicon validation, Silicon Patterns delivers end-to-end custom silicon solutions tailored to complex and high-performance applications. Backed by a strong engineering team and a track record of successful tape-outs, Silicon Patterns helps customers transform ambitious ideas into silicon excellence—faster, smarter, and with reduced risk.